Construction Product Regulation – Certification

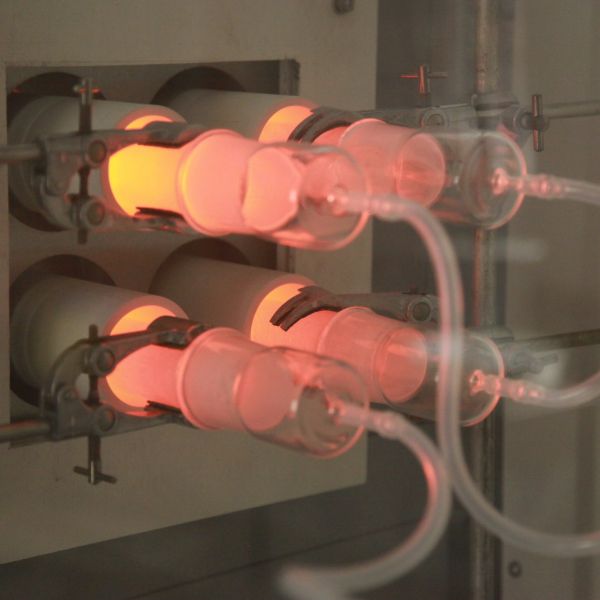

As a designated Notified Body NB 2851 via INAB for the CPR System 1+ you can access testing and fire classification of cables in line with CPR, enabling manufacturers and distributors around the world to supply within the EU.

BASEC Conformity Limited (BCL) is a global leader in the testing and certification of cables. Investment in new equipment allows BCL to test to all the requirements of CPR in respect of cables, providing a full service to manufacturers and traders.

What is CPR?

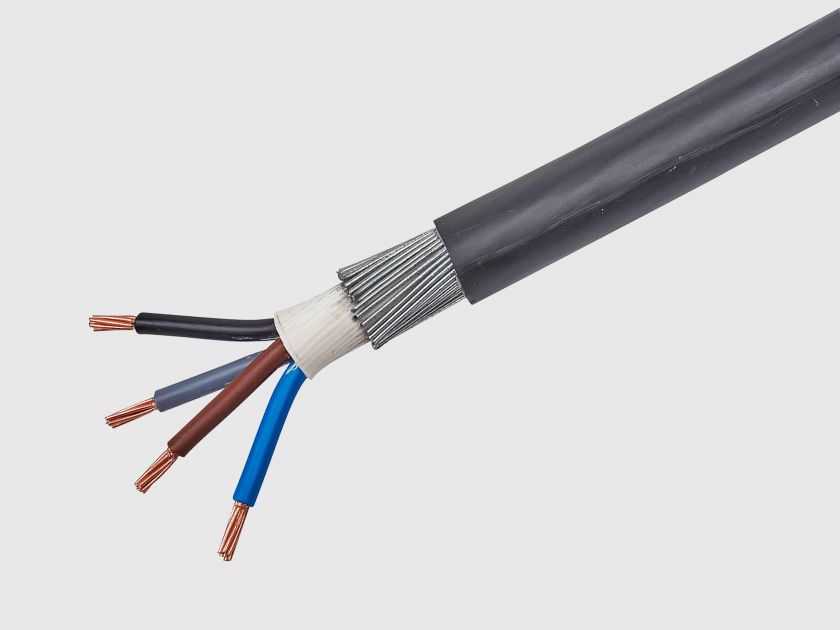

As of 1st July 2017 under the European Construction Products Regulation (CPR), it is now mandatory for cable manufacturers and suppliers to apply CE marking to any products covered by the harmonised European standard EN 50575. The CPR applies to all cables placed on the market for use in fixed installation in domestic, commercial and industrial premises and other civil engineering works anywhere in the European Union. It applies to power, communications and fibre optic cables irrespective of the place of manufacture and includes novel/unique cables and those which are not designed to any particular design standard. These tests, with a few exceptions need to be carried out by an independent Notified Body.

The Construction Products Regulation is solely concerned with reaction to fire and resistance to fire properties of these products, resulting in awarding classifications often known as “Euroclasses” to each product or family of products. The CPR regime for resistance to fire of cables is still under development at the present time.

The process for gaining CPR

- The manufacturer chooses cable/ranges for compliance.

- The manufacturer chooses intended class based on the regulation and market requirements.